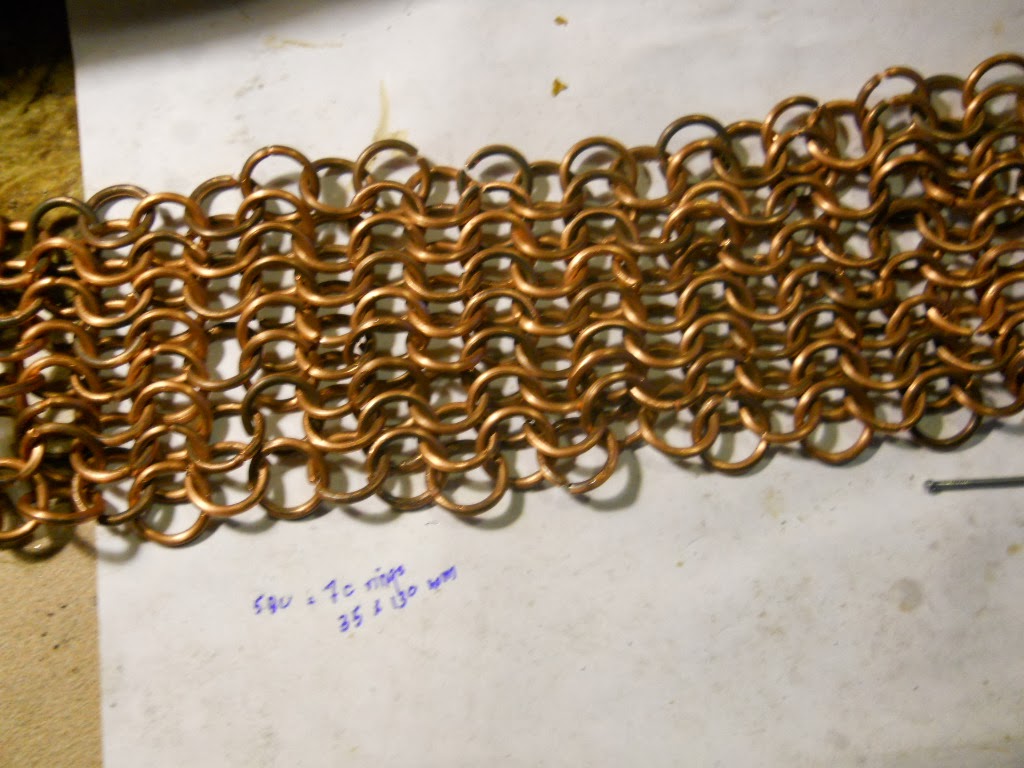

Christmas is over. So everyone has their presents. So now I can show some of the constructions! For my daughter I made a copper/brass mail thingie. Call it a necklace or call it a wall hanging, doesen't matter. Didn't get pictures of it. Here are some of the construction steps for another one.This is for a dear friend. It is a "necklace" of sorts. It could also be used for a wall hanging. It is made out of salvaged copper wire. And other things.

I made a maltese cross out of sheet copper that I happened to find in an antique shop! In the middle of it is a mandala. Well, maybe it isn't really a mandala. It is in fact a piece of a defunct VCR player, which I deconstructed. Remember those? Does anyone remember a videocassete? The coil was so elegant that I knew its ultimate fate was to become a mandala. Sitting off to the right is the neck chain. This is a copper/brass single-strand contraption. In order to be artistic it was very, very slender wire, what bead-stringers use. One uses what one can find in Alaska. It was so flimsy I had to solder all of the brass rings. This was a lot of work, but I couldn't have things coming apart. Unseemly language was used in the construction. Contrrary to popular belief, it does not help at all, but it eases frustration.

Fortunately my butane torch behaved itself, as it seldom does in winter. I used silver solder, much stronger than the lead solder used for electrical work.

Above, the top of the "necklace" has had a wire rod soldered to it. This will keep it from sagging. The neck chain has been tied in and soldered. I happen to like the intersection of art and technology. Just as well, because otherwise this piece would have driven me crazy.

I really like this piece. It is all proper chain mail. It is also symbolic, but I will leave this aspect to the art critics. They have to make a living too, after all.

Best lettuce!

2 weeks ago